Tube Laser Cutting Systems Uses

It doesn't take much to make your in-house laser tube cutters easy or cost-prohibitive. Everyone can cut like a pro, even engineers.

Lasertube can help you make improvements to parts based on your customers' needs.

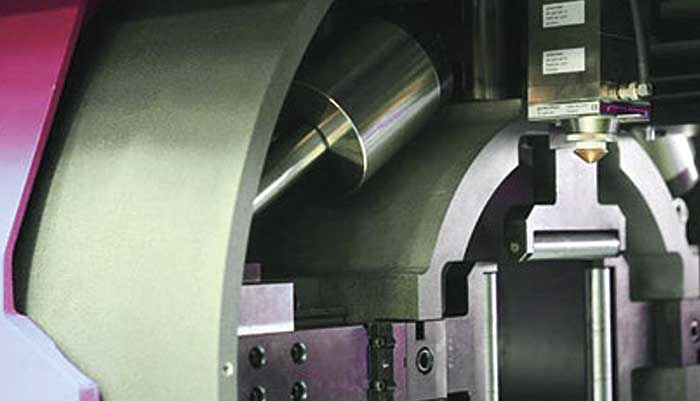

Tube Laser Cutting Systems Nozzle

Let's see below the advantages of using an Automatic Tube and Section Bar Storage System with a Lasertube Cutting System.

Lasertube systems can be used to develop new applications and improve existing ones. This allows you to enter new industrial sectors, increasing profits, and allowing for new opportunities.

Tube Laser Cutting Systems EngineerWith Lasertube systems, you can create new applications or improve existing ones, entering new industrial sectors and increasing profit margins.

Many thought fiber lasers could only be used for thin materials at one time. Due to its longer wavelength, CO2 produced enough kerf for the cutting of thick materials so that there was enough room for material removal. However, the fiber laser wasn't able to produce the same kerf in thicker materials. The problem was solved in recent years by collimating technology which allows for a wider beam of fiber laser-generated light that can be used to create materials separation. Because the beam width can be switched, the machine can use a narrower beam to process thin material. This makes it possible for the machine to process different-sized materials faster on the same fiber laser cutter machine.

It doesn't take much to make your in-house laser tube cutters easy or cost-prohibitive. Everyone can cut like a pro, even engineers.

Lasertube can help you make improvements to parts based on your customers' needs.

It's 1/3 of a full 20-foot (248") tube making it convenient for you to make 3 pieces of stock. This allows for you to still purchase full tubes lengths without wasting any material.

There are many ways to use processed tubes and profiles. It can be used in automotive, furniture design, architecture, and commercial vehicle construction. The laser-assisted processing (profiles and tubes) offers a wide range of manufacturing options and unique design possibilities in many industries.

Each application requires a different cutting technology. Depending on the type of material and desired productivity and cutting quality, users can choose from CO2 or fiber laser systems.

The fully-automatic solution that guarantees maximum productivity and fast production changes.Tube Ø Range min. 0.47" (12 mm) - max. 6" (152.4 mm)3D cutting modeFiber laser

Cambus Medical uses Coherent StarCut Tube, a laser-powered tube cutter machine powered by lasers, and Select Laser Welders for business success.

The CO2 reactor is larger and consumes more energy. To produce the laser beam, electricity is added to a mixture gas mixture. Mirrors are used to increase the intensity of light, and prepare it for exiting a resonator. The beam must travel through the path of several cooled reflectors until it reaches lens once it has left the resonance. This travel can cause a loss of power or quality in the laser beam.

To close the time gap when it comes to tube checks, some machinery manufacturers are using cameras for these checks. They reduce the quality check to about half a second and also reduce the number of rotations that are required. This allows the machine to retain productivity as well as accuracy.

The StarCut Tube SL is a complete turnkey machine that incorporates an fs-laser and is ideal for laser cutting complex metal shapes such as thrombectomy stent retrievers.